Filter Options

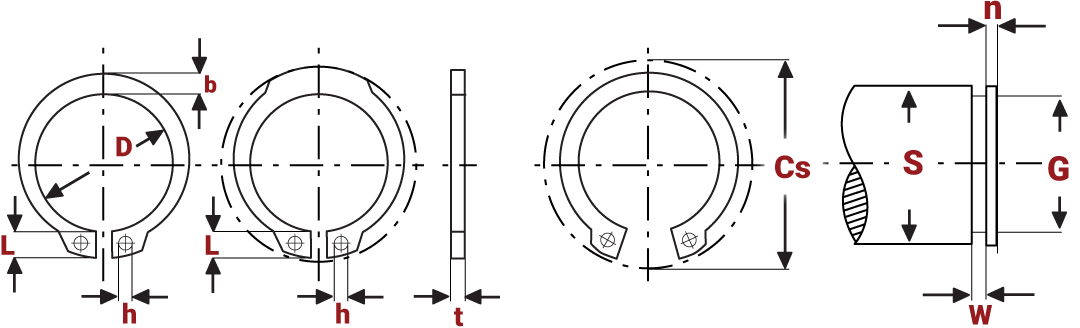

Heavy Duty External Circlips: To DIN 471 Metric

Design is based upon the standard external series but with increased thickness and in the case of the American series increased section depth. Heavy duty Circlips are used to withstand shock loads and also to resist conical deformation where, for example, large abutment radii are present.

Standard material: Carbon Spring Steel – Standard Finish: Phosphate and Oil.

Also availabe: Heavy Duty External Circlips: N1460 American Specification

Display Price: Per 100 unitsPer single unit Per 100 unitsPer single unit

| Name | Shaft (S) | Thick (t) | Thickness Tolerance | Free Diameter (D) | Clearance on Shaft (Cs) | Beam (b) | Lug (L) | Hole Diamter (h) | Ring Load Carrying Capacity (kN) | Groove Diameter (G) | Groove Tolerance | Groove Width (W) | Edge Margin (n) | Groove Load Capacity |

|---|